|

|

|

Continuous Improvement is an ongoing journey … one that requires leadership.

The first critical steps for business leaders who want to embark on this journey are:

These decisions constitute a commitment to become a learning organization which represents the glue that hold all future continuous improvement activities together. The next step is to begin to affect change by:

This step is the cornerstone of Keep Getting Better. Here a proposed change is tested for whether or not it creates positive change for the organization. If it does then it is adopted as the current standard of work. If not, the existing method stands. Doing this hundreds and thousands of times, over and over is how continuous improvement happens.

Beyond these steps, however, the devil is in the details. It is ironic that in a philosophy that promotes consistent processes that there is not one perfect way to deploy Continuous Improvement concepts. Although many have tried to find this Holy Grail, all have failed. The reason is that the most critical ingredient in Continuous Improvement is people and people of course are totally unique. So it stands to reason that one method does not work for all situations and the best we can do is agree on principles and leave the application as an art.

Fortunately that is what has occurred. The trial and error of others has yielded a series of concepts and best practices; a common language; something that has been derived over time and has been proven in real situations time after time. This body of knowledge is commonly referred to as many things like Lean, Six Sigma, TQM and others, but in the end it all comes down to the PDCA cycle; Plan … Do … Check … Act.

From there every situation is just a little different. It requires the artful combination of best practices, common sense, discipline and devotion.

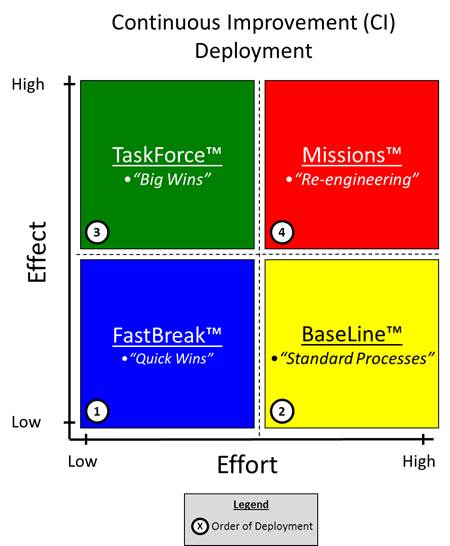

After twenty plus years of training, practice, participation and counseling, JEL subscribes to the following model for deployment. To put it in words would be as follows:

-

Start simple, learn the fundamentals, and work on some easier problems. This requires lessor effort, and yields some positive effect. It creates the first taste of successes, though not as significant as what will be possible over time.

-

Next, learn more about specific techniques and carefully define processes. This requires a higher level of effort and in the short-term still generates only moderate effect. However it creates the foundation for later, more-significant success; much like building the foundation of any building or structure, if you get that right, the rest is much easier.

-

Once the foundational elements are in place, it is possible to move on to more significant improvement activities; this work requires higher skill and takes more time, but results in more significant improvements and savings.

-

From there, entire processes can be reinvented or new products developed; these solutions are much more efficient and effective from the start and require less modification over time to achieve desired results. This requires greater effort but can yield the most dramatic of effects, especially with new products or processes.

Below is a graphical representation of this model that ties the previous concepts together.

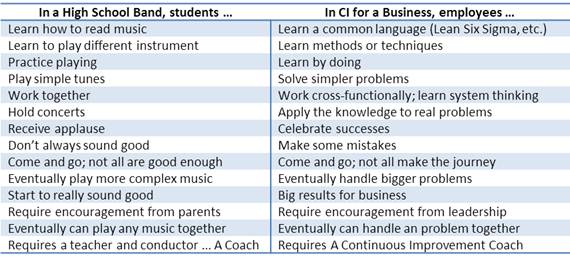

The comparison below creates the proper perspective required for implementing Continuous Improvement (CI). This example compares creating a musical band (like a High School Band) to Continuous Improvement.

|